Airless shot blasting machines come in various configurations and designs, each tailored to meet specific surface preparation and cleaning requirements. Understanding the different types of airless shot blasting machines can help businesses select the most suitable equipment for their applications. In this blog, we’ll provide a comparative analysis of the common types of airless shot blasting machines.

1. Wheel Blasting Machines:

Wheel blasting machines are the most widely used type of airless shot blasting equipment. They consist of one or multiple wheels equipped with blades or paddles, which accelerate the abrasive media towards the workpiece. Wheel blasting machines are further classified into two subtypes:

- Centrifugal Wheel Blasting: In this type, the wheel rotates at high speeds, and the centrifugal force propels the abrasive media towards the workpiece.

- Airless (Turbine) Wheel Blasting: Airless wheel blasting machines use an airless wheel, which is powered by a motor to project the abrasive media. They are particularly suitable for delicate or sensitive surfaces that require controlled blasting intensity.

2. Spinner Hanger Shot Blasting Machines:

Spinner hanger shot blasting machines are used for treating smaller workpieces or batches. They consist of a central hanger or hook on which the workpieces are suspended. The hook rotates, ensuring even coverage of the abrasive media over the workpiece surfaces.

3. Tumble Belt Shot Blasting Machines:

Tumble belt shot blasting machines are designed for bulk treatment of small to medium-sized parts. The workpieces are placed on a rubber or metal conveyor belt that tumbles them as they move through the blasting chamber. The abrasive media is continuously propelled onto the tumbling workpieces, providing uniform and efficient cleaning or surface preparation.

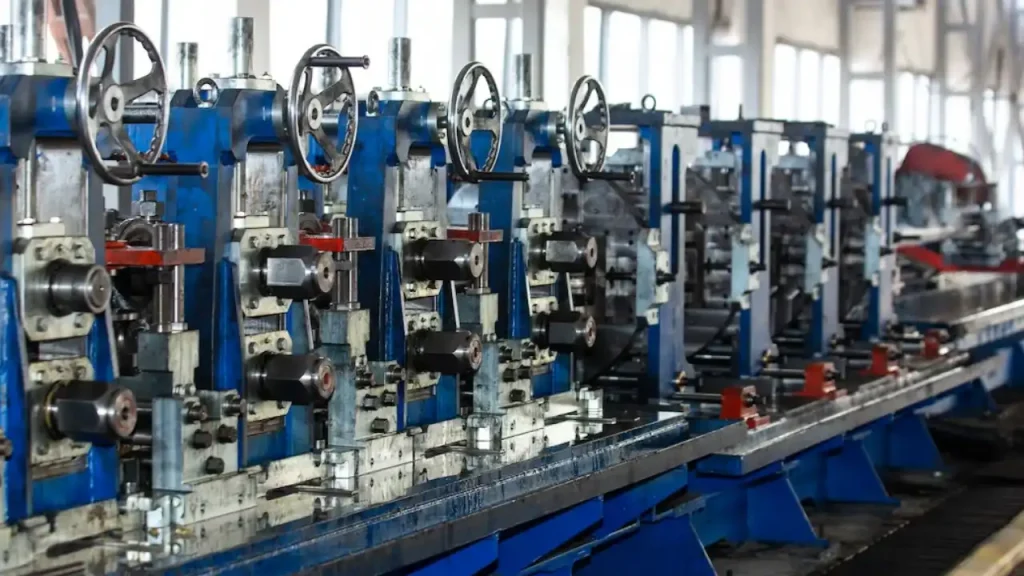

4. Roller Conveyor Shot Blasting Machines:

Roller conveyor shot blasting machines are ideal for treating long, flat, or large components. The workpieces are placed on a continuous roller conveyor that transports them through the blasting chamber. The abrasive media is projected from multiple blast wheels, ensuring comprehensive coverage and efficient cleaning.

The different types of shot blasting equipment available and their uses

Understanding Shot Blasting Machines: A Comprehensive Guide

Advantages of Airless Shot Blasting Machines over Traditional Blasting Methods

5. Table Blast Shot Blasting Machines:

Table blast shot blasting machines are used for heavy-duty applications. The workpiece is placed on a table, which rotates or oscillates to expose all sides of the workpiece to the abrasive stream. These machines are often utilized for cleaning or preparing large, irregularly shaped parts.

Factors to Consider When Choosing Airless Shot Blasting Machines:

- Workpiece Size and Weight: Consider the dimensions and weight of the workpiece to ensure the machine’s capacity aligns with the application requirements.

- Blasting Intensity: Different machines provide varying levels of blasting intensity. Select the appropriate machine depending on the desired surface finish and the material of the workpiece.

- Production Volume: Evaluate the expected production volume to choose a machine that can handle the required throughput efficiently.

- Automation and Controls: Consider the level of automation and control features required for seamless integration into your production processes.

- Abrasives and Dust Collection: Ensure that the machine is compatible with the type of abrasive media you plan to use and that it has an efficient dust collection system.

Conclusion:

Airless shot blasting machines are versatile and indispensable tools for achieving superior surface preparation and cleaning in diverse industries. By understanding the different types of airless shot blasting machines and considering essential factors, businesses can make informed decisions and invest in the right equipment to enhance their surface treatment processes and overall productivity.