- Cleaning welded structures and fabrications

- Descaling of forged or heat treated parts

- Desanding of ferrous and non-ferrous metal castings

- Deburring of metallic and non-metallic parts

- Deflashing of die cast parts

- Contaminant removal

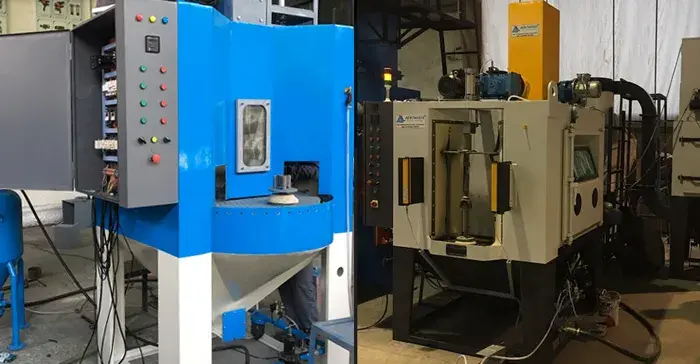

How Our Rotary Indexing Machines Work

Our rotary indexing machines work on the suction blasting principle. The machine has a bearing-mounted indexing turntable with a number of indexing positions. One indexing satellite stands outside the blast cabinet for job loading and unloading, while other satellites stand inside the blast cabinet (one in blasting operation and others are in queue). The indexing turntable is driven by a geared drive.

After the required finish is obtained, the indexing table rotates again by a specified degree so that the next satellite having a new job for blasting comes under the blasting area and the blast job comes to the loading and unloading area.

Features of Our Rotary Indexing Machines

- Single fixed table or dual mobile turntables

- Can treat components weighing up to 120 tons

- Suitable for various shapes and dimensions, casts, forged parts, pressed parts, steel, and non-ferrous metal parts and parts made from fragile materials

- Can be equipped with fixtures and accessories built according to the pieces to be treated

Benefits of Using Our Rotary Indexing Machines

- Improved cleaning efficiency

- Reduced labor costs

- Increased productivity

- Improved product quality

If you are looking for a rotary indexing machine that can meet your specific needs, contact Aerowheel today. We have a wide range of machines to choose from, and we can also custom design a machine to your specifications.

How Shot Blasting Machines Work?

Choosing the Right Shot Blasting Machine for Your Needs

Emerging Trends in Shot Blasting Machines: Insights from Leading Manufacturers in India

In addition to the features listed above, our rotary indexing machines also offer the following benefits:

- Durability: Our machines are made from high-quality materials and are designed to last for years.

- Ease of operation: Our machines are easy to operate and maintain, even for those with no prior experience.

- Safety: Our machines are equipped with a number of safety features to protect operators from harm.

We are confident that our rotary indexing machines are the best on the market. We offer competitive prices and excellent customer service. We also have a team of experienced engineers who can help you choose the right machine for your needs.

Contact us today to learn more about our rotary indexing machines.

Reviews

There are no reviews yet.