Shot Peening Machine Price And Quantity

| Minimum Order Quantity | 1 Unit | Price Range | 1000000.00 – 6000000.00 INR/Unit |

Shot Peening Machine Product Specifications

| Color | Blue | Power Source | Electricity |

| Operating Type | Automatic | Surface Treatment | Painted |

| Product Type | Shot Peening Machine | Usage & Applications | Industrial |

| Power | 220 Volt (v) |

Shot Peening Machine Trade Information

| Supply Ability | 10 Unit Per Day | Delivery Time | 2-4 Weeks |

| Main Domestic Market | All India |

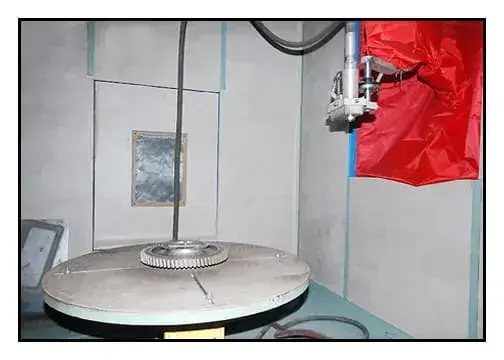

What is Shot Peening?

Shot peening is a cold working process that uses tiny metallic or ceramic beads to bombard the surface of a component. This bombardment creates tiny dimples on the surface, inducing compressive residual stress. This compressive stress counteracts the tensile stress caused by factors like bending and twisting, ultimately extending the fatigue life of the component.

Benefits of Shot Peening:

- Increased Fatigue Life: Shot peening significantly increases the fatigue life of components, allowing them to withstand millions of more stress cycles before failure.

- Enhanced Strength: The compressive stress layer created by shot peening improves the overall strength of the component, making it more resistant to cracking and breakage.

- Reduced Stress Corrosion Cracking: Shot peening closes microscopic cracks on the surface, making the component less susceptible to stress corrosion cracking.

- Improved Finish: Shot peening can also improve the surface finish of components, making them smoother and more aesthetically pleasing.

Applications of Shot Peening:

Shot peening is widely used in various industries, including:

- Automotive: Shot peening is used on critical components like gears, shafts, and springs to improve their fatigue life and prevent premature failure.

- Aerospace: Shot peening is essential for ensuring the safety and reliability of aircraft components like engine blades, landing gear, and fuselage panels.

- Medical: Shot peening is used on medical implants and prosthetics to improve their durability and biocompatibility.

- Oil and Gas: Shot peening is used on drill bits and other downhole equipment to extend their service life and improve performance.

Aerowheel’s Shot Peening Machines:

Aerowheel offers a wide range of shot peening machines to cater to the diverse needs of our customers. Our machines are known for their:

Applications of Wet Blast Cabinets in Precision Industries

Custom Sand Blasting Solutions by Leading Manufacturers

Importance of Ventilation and Fume Extraction

- Durability and Reliability: We use high-quality materials and components to ensure that our machines last for years.

- Efficiency and Productivity: Our machines are designed to provide quick and efficient shot peening operations.

- Customization: We offer a variety of options and features to tailor our machines to your specific requirements.

- Safety: We prioritize operator safety with features like blast guards, interlock systems, and emergency shut-off buttons.

- After-sales Support: We provide comprehensive after-sales support, including technical assistance, spare parts, and maintenance services.

Investing in Aerowheel Shot Peening Machines

An Aerowheel shot peening machine is an investment in quality, productivity, and long-term savings. By extending the fatigue life of your components, you can reduce downtime, maintenance costs, and the risk of accidents.

Contact us today to learn more about how Aerowheel can help you improve the performance and reliability of your components with shot peening.

Additional Information:

- For a more in-depth understanding of shot peening, you can read our blog post: What is Shot Peening?

- We also offer a variety of resources on our website, including:

- A library of white papers on shot peening applications

- Case studies of successful shot peening projects

- A glossary of shot peening terms

Reviews

There are no reviews yet.