Hanger Shot Blasting Machine Price And Quantity

| Minimum Order Quantity | 1 Piece | Price | 100000 – 10000000 INR/Piece |

Hanger Shot Blasting Machine Product Specifications

| General Use | Industrial | Computerized | No |

| Automatic | Yes | Surface Treatment | Painted |

| Material | Other | Voltage | 220 Volt (v) |

| Product Type | Hanger Shot Blasting Machine | Color | Blue |

Hanger Shot Blasting Machine Trade Information

| Supply Ability | 10 Piece Per Day | Delivery Time | 2-4 Weeks |

| Main Domestic Market | All India |

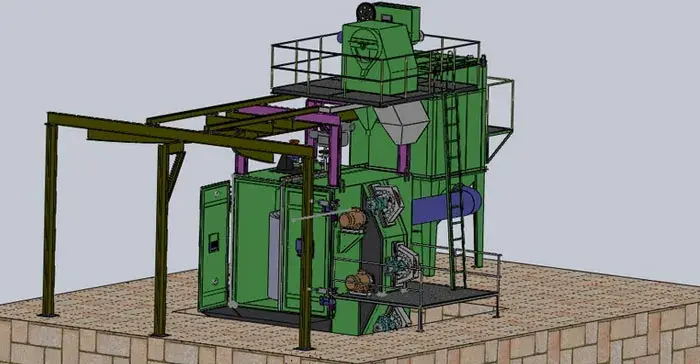

Unleashing the Power of the Hanging Revolution:

Imagine components gracefully suspended within a robust chamber, bathed in a controlled storm of abrasive media. The Hanger Shot Blasting Machine unlocks this transformative power, gently rotating your workpieces for exceptional 360-degree cleaning. No surface is left untouched, leaving you with pristine results regardless of complexity.

Why Choose Aerowheel Hanger Shot Blasting Machines?

- Tailor-Made Solutions: Unlike rigid manufacturers, Aerowheel welcomes your vision. We build your dream machine, crafting the perfect Hanger Shot Blasting solution to meet your exact specifications.

- Unwavering Quality: Every stage of our development process undergoes rigorous inspection, ensuring exceptional performance and a machine built to last.

- Expert Support: Our dedicated team stands by you. From comprehensive spare parts inventories to specialized services, we’re here to keep your machine running smoothly.

- Global Reach: We cater to clients across India and beyond, delivering innovative solutions worldwide.

Three Powerhouses to Choose From:

- Closed Loop Hanger Shot Blasting Machine: This eco-friendly champion boasts a self-contained abrasive recycling system, minimizing waste and maximizing cost-effectiveness.

- Y Type Spinner Hanger Shot Blasting Machine: Experience unmatched efficiency with the rapid rotation of this dynamic machine, ideal for high-volume cleaning tasks.

- Gate Type Spinner Hanger Shot Blasting Machine: Tackle larger, heavier components with ease. This robust machine offers exceptional access and control for optimal cleaning.

Beyond Versatility: A World of Applications:

The Aerowheel Hanger Shot Blasting Machine opens doors to a multitude of possibilities:

- Blast clean welded steel fabrications: Achieve flawless finishes and remove unwanted imperfections effortlessly.

- Deburr and homogenize diecast parts: Ensure precision results and enhance surface quality for seamless finishing.

- Peen dynamically stressed components: Increase fatigue strength and improve component lifespan through controlled surface peening.

- Remove mill and forge scale, as well as rust: Breathe new life into components by eliminating stubborn residues and restoring pristine surfaces.

- Increase surface roughness: Prepare surfaces for optimal adhesion and enhance paint bonding or coating application.

- Boost fatigue strength: Shot peening strengthens components against stress and wear, extending their lifespan significantly.

Batch or Continuous: Choose Your Cleaning Symphony:

Exploring the Future of Shot and Sand Blasting Technologies

Indian Standards and Guidelines for Industrial Sand Blasting

The Role of Dust Collectors in Blast Rooms

- Batch Type Machines: Perfect for delicate components or smaller batches, these machines offer a controlled cleaning cycle with efficient loading and unloading.

- Continuous Type Machines: Automate your production line with these high-throughput machines, ensuring uninterrupted cleaning and maximizing efficiency.

Aerowheel: Your Partner in Precision Cleaning Excellence:

Investing in an Aerowheel Hanger Shot Blasting Machine is an investment in your business’s success. We offer:

- Unmatched flexibility and customization: Build your dream machine with our expert guidance and craft the perfect cleaning solution for your unique needs.

- Exceptional quality and performance: Every machine is built to last, delivering consistent results and minimizing downtime.

- Dedicated support and service: Our team is always here to assist you, ensuring your machine operates smoothly and efficiently.

- Global reach and expertise: We cater to clients worldwide, offering innovative solutions and unmatched customer service.

Let Aerowheel empower you to conquer any cleaning challenge with the Hanger Shot Blasting Machine. Contact us today and experience the Aerowheel difference!

Remember, Aerowheel: Where Cleaning is an Art, not a Chore.

Reviews

There are no reviews yet.